Weiße Druckfarbe ist eine der teuersten und am häufigsten verwendeten Druckfarben in der Verpackungsproduktion, wird jedoch oft nicht optimal eingesetzt. In diesem Blog erfahren Sie, wie MeasureColor Druckereien in die Lage versetzt, die Opazität von weißer Druckfarbe zu erhöhen, den Ausschuss zu reduzieren und die Druckqualität insgesamt zu steigern.

Warum weiße Druckfarbe so wichtig ist

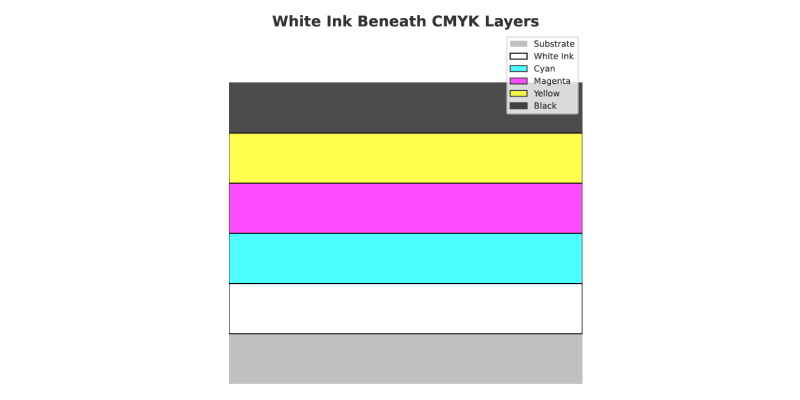

Weiße Druckfarbe dient als Grundlage beim Druck auf transparente, metallische oder farbige Substrate. Sie sorgt für brillante und konstante Markenfarben. Doch aufgrund der hohen Verbrauchsmenge und Kosten von weißer Druckfarbe können Unzulänglichkeiten beim Weißdruck schnell zu übermäßigem Ausschuss und steigenden Materialkosten führen.

Die Herausforderung: Opazität vs. Effizienz

Standardmäßig verwenden viele Druckereien Weißschichten mit hoher Opazität, um visuell ansprechende Ergebnisse zu gewährleisten. Dies führt jedoch häufig zu einem übermäßigen Verbrauch an weißer Druckfarbe. Mit MeasureColor haben Druckereien eine genaue Kontrolle und einen Überblick in Echtzeit über die Opazität von Weiß, sodass sie die Qualität ohne überhöhte Ausgaben aufrechterhalten können.

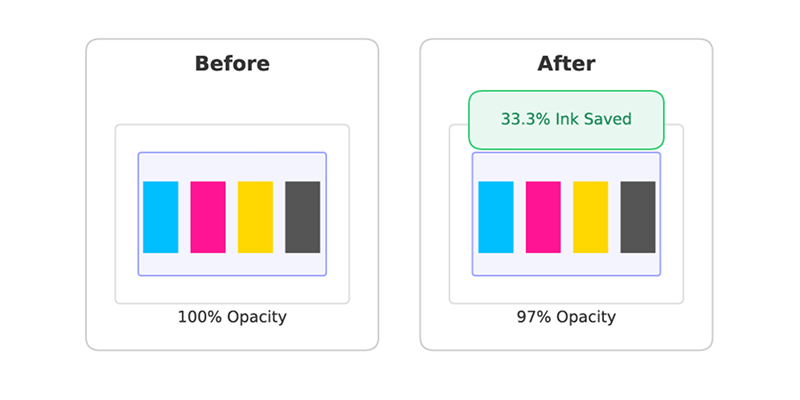

Der Durchbruch: Änderung der Opazität um 3 % = Einsparung von Druckfarben um 33,3 %

Kleine Änderungen können eine große Wirkung haben. Durch eine Verringerung der Opazität von Weiß um nur 3 % kann der Farbverbrauch um 33,3 % verringert werden – ohne sichtbare Auswirkungen auf die Druckqualität. MeasureColor macht es einfach, diese „goldene Mitte“ zwischen Leistung und Effizienz zu finden.

Wie MeasureColor hilft

Die Software von MeasureColor liefert leicht zu interpretierende Grafiken und konkret verwertbare Daten, die Druckmaschinenbedienern bei Folgendem helfen:

- Überwachung des Deckvermögens in Echtzeit

- Anzeige historischer Leistungsdaten für Aufträge und Substrate

- Schnelle, fundierte Entscheidungen zur Optimierung des Farbverbrauchs

Ganz gleich, ob Sie Etiketten, Faltschachteln oder flexible Verpackungen drucken, lässt sich MeasureColor nahtlos in Ihren Workflow integrieren.

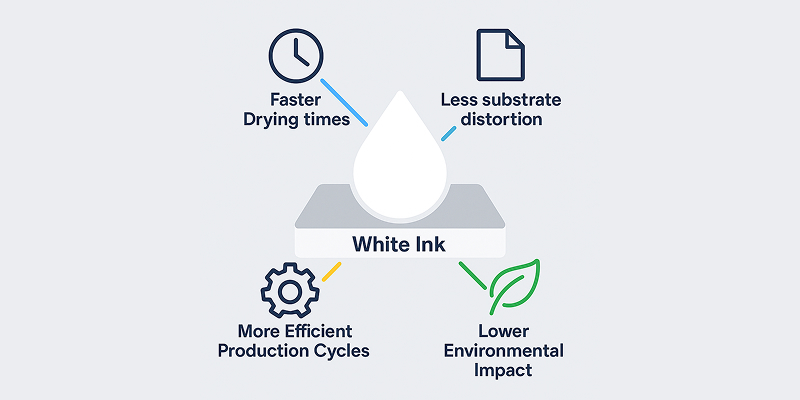

Nicht nur Kosteneinsparungen, sondern auch operative Vorteile

Die Reduzierung des Verbrauchs an weißer Druckfarbe hat Auswirkungen auf den gesamten Drucksaal:

- schnellere Trocknung

- geringere Verformung des Substrats

- effizientere Produktionszyklen

- geringere Umweltbelastung

MeasureColor unterstützt einen intelligenteren, nachhaltigeren Ansatz zum Drucken.

Erste Schritte mit MeasureColor

Die Optimierung der Opazität von Weiß erfordert keine großen Prozessänderungen. Mit den Tools und der intuitiven Benutzeroberfläche von MeasureColor können Teams noch heute mit der Messung und Verwaltung von weißer Druckfarbe beginnen.

Fazit

Für viele Verpackungsdruckereien ist die Weiß-Optimierung eine versteckte Chance. Mit MeasureColor verfügen Sie über die notwendigen Tools, um Kosteneinsparungen zu erzielen, eine hohe Druckqualität zu gewährleisten und effizienter zu arbeiten – indem Sie einfach messen, was wichtig ist.

Blog-Serie „MeasureColor in Aktion“ weiterlesen

Dieser Artikel ist Teil unserer Serie MeasureColor in Aktion. Informieren Sie sich über frühere Themen:

- Nr. 1 MeasureColor: eine benutzerfreundliche Oberfläche für schnellere Druckentscheidungen

Erfahren Sie, wie ChromaTrack Bedienern ohne zeitaufwendiges Ausprobieren dabei hilft, durch vorausschauende Korrekturen schneller die richtige Farbe zu erzielen. - Nr. 2 MeasureColor: zuverlässige Verwaltung digitaler Farbvorgaben

Erfahren Sie, wie Reference Manager die Organisation und Anwendung von digitalen Farbvorgaben und ICC-Profilen vereinfacht und so für Workflow-unabhängige, konstante Ergebnisse sorgt. - Nr. 3 MeasureColor: bessere Druckqualität durch Optimierung der Tonwertzunahme

Sehen Sie, wie die Überwachung der Tonwertzunahme in Echtzeit und die Optimierung der CTP-Kurve Druckmaschinenbedienern dabei hilft, die Farbpräzision zu erhöhen, den Ausschuss zu reduzieren und die Farbkonstanz zu wahren.

Sprechen Sie mit unseren Farbexperten, um zu erfahren, wie Sie die Opazität von Weiß mit MeasureColor präzise und zuverlässig im Griff haben.